ACCESSORIES

BUSBAR

A Busbar is a rigid electrical conductor (usually made of copper or aluminum) used to distribute high electrical power safely and efficiently. In EOT cranes, busbars supply continuous power to moving components like crane bridges, hoists, and trolleys.

Key Functions:

Supplies power to long-travel and cross-travel motions

Ensures stable voltage during crane operation

Reduces power loss and maintenance

CURRENT COLLECTOR

A current collector is a power-pickup device used in electric cranes (like EOT cranes, overhead cranes, gantry cranes, etc.) to transfer electrical power from a fixed conductor system (such as busbars or rail conductors) to the moving crane equipment. It allows the crane to receive continuous electrical energy even while moving along the rail.

GEARED MOTOR

A geared motor is an integrated unit consisting of an electric motor and a gearbox, designed to deliver high torque at controlled low speeds. In cranes, geared motors are essential for precise, smooth, and safe movement of loads.

Purpose of Geared Motor in Cranes

Geared motors are used to:

Reduce motor speed to usable crane operating speed

Increase torque for lifting and movement

Ensure smooth start, stop, and controlled motion

Handle heavy loads safely and efficiently

FESTOON TRACK

A festoon track is a steel or C-channel track installed along the crane runway or bridge. Electrical cables are suspended from trolleys that move freely inside the track as the crane travels.

Purpose of Festoon System

Supplies power and control signals to crane motions

Manages cable movement safely

Prevents cable twisting, dragging, or damage

Ensures smooth and reliable crane operation

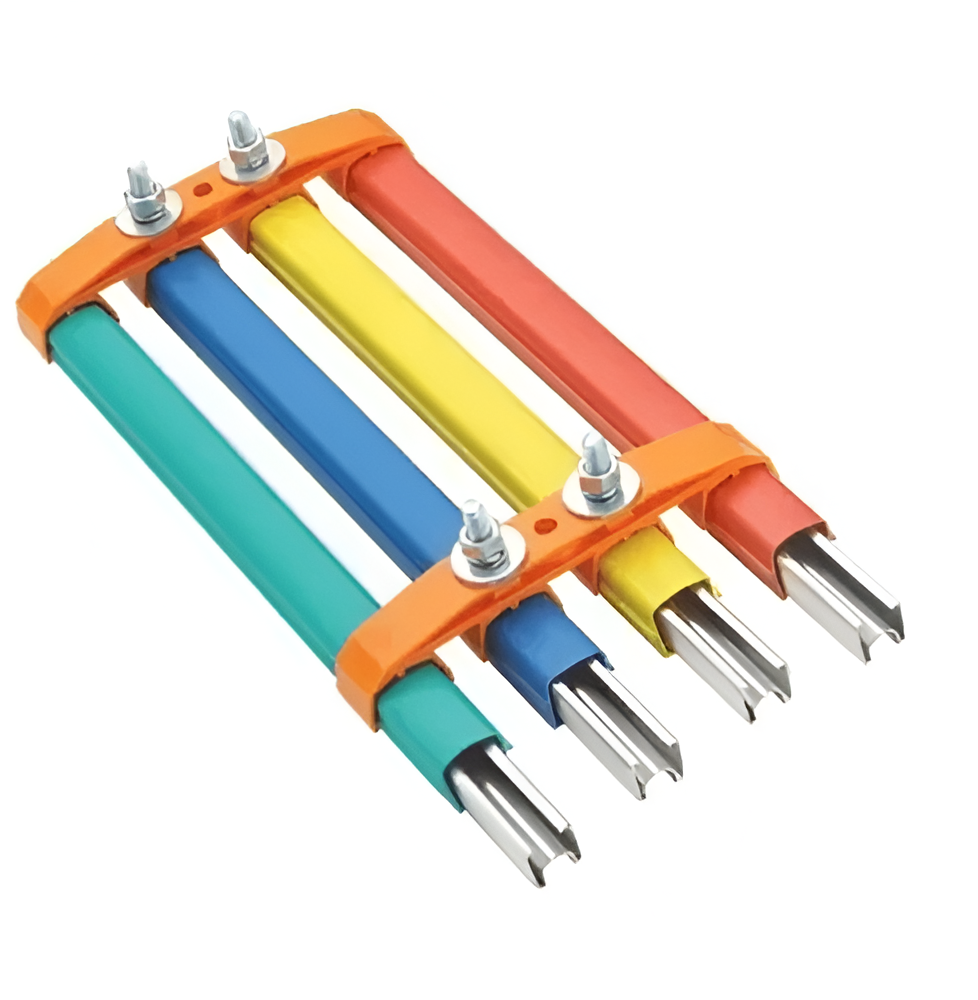

BUSBAR ASSEMBLY

A busbar assembly is a complete power-supply system used in cranes to safely transmit electrical power to moving equipment like hoist, trolley, and long travel.

Main Components of Busbar Assembly:

- Busbar Conductor

- Busbar Housing

- Current Collector (Collector Shoe)

- Joint Connectors

- Hanger / Clamp Brackets

- Expansion Joint

LIFTING BELT

A belt in a crane is a power transmission component used to transfer motion and torque from a motor to another rotating part, such as a gearbox, drum, or auxiliary mechanism.

Where Belts Are Used in Cranes

Belts are not used in main hoisting drives of EOT cranes, but they are commonly used in:

🔹 Trolley travel mechanisms

🔹 Long travel auxiliary drives

🔹 Cooling fans of motors

🔹 Control panel ventilation

🔹 Small auxiliary lifting or positioning units

REMOTE

A remote control in a crane is a wireless handheld device used to operate crane movements safely from a distance. It allows the operator to control lifting, lowering, and traveling functions without sitting in a cabin or using pendant controls.

Main Functions Controlled by Remote

Hoisting (Up / Down)

Long Travel (Forward / Reverse)

Cross Travel (Left / Right)

Trolley Movement

Emergency Stop

Speed Control (Single or Dual Speed)

ROPE GUIDE

A Rope Guide is an essential mechanical component used mainly in wire rope hoists and EOT cranes. Its primary function is to guide the wire rope evenly onto the hoist drum during lifting and lowering operations.

Purpose of Rope Guide

Ensures proper winding of wire rope on the drum

Prevents overlapping, tangling, and crushing of the rope

Improves rope life and hoist efficiency

Ensures smooth and safe crane operation

SYTCO BRAKE

A SYTCO brake refers to a type of fail-safe electromagnetic brake commonly used in industrial material-handling equipment like cranes, hoists, and lifts.

- These brakes are electromagnetic, single-disc, and AC-powered designs.

They are fail-safe: if electrical power is lost, springs automatically clamp the brake to stop movement and hold the load safely. SY

Typical usage is on hoists and crane motions where holding position and emergency stopping are critical.

DBR (Dynamic breaking resistor)

DBR (Dynamic Braking Resistor) is a safety and control component used with VFD / inverter-driven crane motors.

It dissipates excess electrical energy as heat during braking, preventing damage to the drive.

Why DBR is Required in Cranes

When a crane:

Lowers a load

Stops suddenly

Decelerates a moving load

HOOK

A crane hook is a critical load-lifting component used to connect the crane’s hoisting mechanism to the load. It directly carries the load, so strength, safety, and regular inspection are essential.

Purpose of a Crane Hook

-

To lift, hold, and lower loads safely

-

Acts as the link between the crane and the load

-

Designed to withstand high tensile and dynamic forces

WIRE ROPE

A wire rope is a strong, flexible lifting medium made of multiple steel wires twisted into strands and then wound around a core. In cranes, it is used for lifting, lowering, and moving loads safely.

Function of Wire Rope in Crane

Lifts and lowers the load

Transfers load from hook to hoist drum

Ensures smooth and controlled crane operation

Provides high tensile strength and flexibility